Navigating Uncertainties: 5 Supply Management Strategies for Success

Sponsored Content

BDO Supply Management Organizational Future Readiness Assessment (qualtrics.com)

A March 2020 study from Institute for Supply Management® (ISM®) found that 81 percent of U.S. companies expected their procurement operations to be affected by the coronavirus pandemic. Now, more than four years later, we find that supply chains have been substantially altered by the COVID-19, but many procurement organizations have not transformed themselves.

Threats continue to loom — geopolitical tensions, ongoing macroeconomic uncertainty and climate change, to name a few. A company’s ability to anticipate and navigate multiple sources of supply chain disruption is increasingly a source of competitive differentiation.

Unfortunately, many of the actions taken by companies in response to the pandemic and its immediate aftermath are ill-suited to current market conditions and are likely to limit the ability to respond to future threats and capitalize on new opportunities. We recommend five strategies to pivot to in the current market conditions and increase resiliency in the face of uncertainty.

1. Renegotiate Supplier Agreements

The pandemic-era mentality of signing any agreement that might support supply continuity has left many companies saddled with supplier agreements predicated on high inflation and scarcity of supply. With inflation substantially below recent peaks, procurement organizations need to systematically analyze their major supplier contracts and renegotiate them in line with current and future market conditions.

The way renegotiations are handled is critical. Many companies reopen agreements in response to crises, as with the massive supply chain disruptions wrought by COVID-19, or when they or their suppliers are under significant financial pressure, as with the recent period of high inflation. Negotiations under conditions of urgency and stress almost never produce agreements that are optimized for post-crisis conditions. As inflation has receded significantly and supply markets have stabilized, now is the time to engage suppliers on strategic negotiations focused on mutual benefit and building the resilience necessary to survive and thrive together in the face of future uncertainty.

2. Build Relational Resiliency

While cost reduction will always be important, working to minimize revenue losses should continue to be a priority for supply management organizations. This means that supply chain and procurement teams must place significant emphasis on identifying and preempting supply chain bottlenecks and breakdowns.

Companies that invest in creating transparent, high-trust relationships with suppliers and putting supply chain risk monitoring systems in place reap significant benefits when the next crisis emerges — which it inevitably does. Companies that have given their suppliers reason to distrust them will pay a high price — experiencing costly supply chain disruptions as their suppliers take defensive action and shift their attention to other, more profitable customers.

Source: Multiyear study of more than 500 companies conducted by the authors.

3. Disintermediate Your Supply Chain

Years of supply shortages led many companies to increase their reliance on distributors, brokers and other supply chain intermediaries. While these additional supply channels can expand access to supply sources and provide convenience, they also introduce an extra layer of cost, complicate communications, and limit a company’s ability to build close partnerships with key suppliers. Now is the time to scrutinize distributor and broker relationships and consider opportunities for disintermediation in a way that wasn’t possible when the focus was maintaining continuity of supply by any means necessary.

Businesses should focus specifically on reducing both risk and costs by establishing more direct linkage with original equipment manufacturer (OEM) suppliers. Too much intermediation in these relationships tends to hamper demand and capacity planning, thereby creating additional supply continuity risk. Closer partnerships with OEM and other key suppliers also enable supply management teams to collaborate on breakthrough cost reduction through joint design or redesign efforts and alignment of technology and product development roadmaps.

4. Cultivate Ecosystem Collaboration

Many companies reacted to the financial stress and uncertainty of the pandemic by squeezing suppliers or shifting risk onto them, rather than working in conjunction with partners across the supply chain to reduce costs and risk for the entire ecosystem. Companies have an opportunity now to create durable competitive advantage by forging new links of collaboration across multiple nodes in their supply chains.

Both costs and supply continuity risks can be reduced by facilitating collaboration across Tier-1 suppliers and critical upstream suppliers of raw materials and key components. For example, many companies face significant risks because key OEM suppliers are dependent on inputs purchased in relatively small amounts. To help mitigate this risk, companies can purchase critical raw materials and basic components and supply them to OEM suppliers, thus reducing cost and risk in a mutually beneficial manner.

Many innovative companies are establishing manufacturing consortiums across multiple suppliers, in some cases going as far as to bring key suppliers across supply chains together in a shared location to work together under one roof, as separate entities but functioning together as a virtually-integrated manufacturing operation. Working in this way streamlines design for manufacturability, demand planning, and logistics management, thereby creating cost efficiencies and competitive advantage far beyond what can be achieved through traditional sourcing strategies.

5. Take a Human-Centric Approach to Generative AI

A few years ago, the supply management community was abuzz with talk about blockchain and how it was going to transform the profession and business operations. Years later, the impact of blockchain is negligible, though its promise remains intriguing. Meanwhile, all eyes are on the potential of generative artificial intelligence (AI).

However, investment in and adoption of generative AI by supply management lags that of other functions. According to a Gartner poll in October 2023, 47 percent of AI investments have been undertaken by customer-facing functions like sales, marketing and customer service) and another 30 percent by IT. Procurement’s investment in generative AI accounts for only 1 percent of total investment. At the same time, cost optimization was the second-most cited focus of generative AI investment (at 26 percent), exceeding a focus on customer experience/retention (24 percent), indicating a clear need and opportunity for supply management organizations to be at the forefront of AI investment and adoption.

As with any new technology, the hype surrounding generative AI exceeds its current capabilities, and risks abound. The New York Times reported in November 2023, citing research by Vectara, that “even in situations designed to prevent it from happening, chatbots invent information at least 3 percent of the time — and as high as 27 percent.” Another threat is “data poisoning” by malicious actors, whether to propagate misinformation or make a chatbot share sensitive information.

Nonetheless, there are significant benefits to be gained from generative AI tools today, not to replace human talent, but to enable buyers, sourcing managers, and supplier relationship managers to focus on more strategic activities. Solutions like Microsoft Copilot and secure versions of OpenAI’s ChatGPT can be deployed with low risk to (1) expedite category strategy research, (2) analyze spend and supplier performance data, (3) expedite contract reviews during negotiations and (4) automate supply chain risk identification.

Human judgment at every step from data analysis to decision-making remains essential, as does investment in training to help supply professionals get the most out of new and rapidly evolving AI tools while minimizing associated risks.

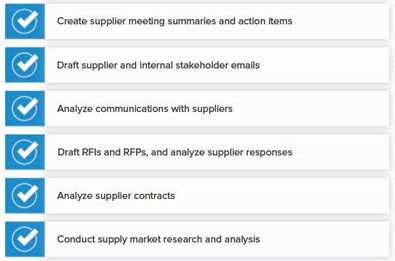

Six Low-Risk Ways to Leverage Generative AI

COVID-19 prompted many C-suite leaders and investment analysts to reassess how critical the supply management function is to business success. With the last crisis behind us but an uncertain future ahead, now is the time for procurement and supply chain professionals to lead efforts to prepare for what comes next.

***

Ashley Hetrick is a principal and leader of BDO USA’s sourcing and supply chain practice, and Jonathan Hughes is the national managing principal and global practice leader of BDO USA’s management consulting practice. They can be reached at ahetrick@bdo.com and jonathan.hughes@bdo.com. They will be presenting on these ideas and others at the ISM World 2024 Annual Conference in Las Vegas on April 29-May 1.

A version of this article authored by Jonathan Hughes originally appeared in the May/June 2020 issue of Supply Chain Management Review. The underlying concepts are applicable in today’s market environment.