Inside Supply Management Magazine

The Sources of Future Supply Chain Restlessness

(Editor’s note: Collaborating with the U.S. Pan Asian American Chamber of Commerce (USPAACC) Education Foundation and with USPAACC CPO members, Howard University School of Business supply chain students interviewed procurement thought leaders and conducted other research to identify emerging issues disrupting supply chains in 10 primary global industries. Students, who conducted research for five months beginning in September 2018, compiled their results in a report, What Will Keep the Next Generation of Supply Chain Leaders Awake at Night? Report recommendations to mitigate or eliminate future disruptor nightmares were featured in the May/June issue of Inside Supply Management® magazine.)

Supply chain disruptions have continued to grow significantly in recent years, even before the coronavirus (COVID-19) pandemic struck and caused a major impact on the availability of components, goods and services as well as logistics, shipping and sourcing. Our research shows that (1) common disruptors have direct business impacts across all industries and (2) other disruptors are evolving and relevant to a smaller group of industries. Half of CPOs interviewed anticipate these dynamics to intensify in the future.

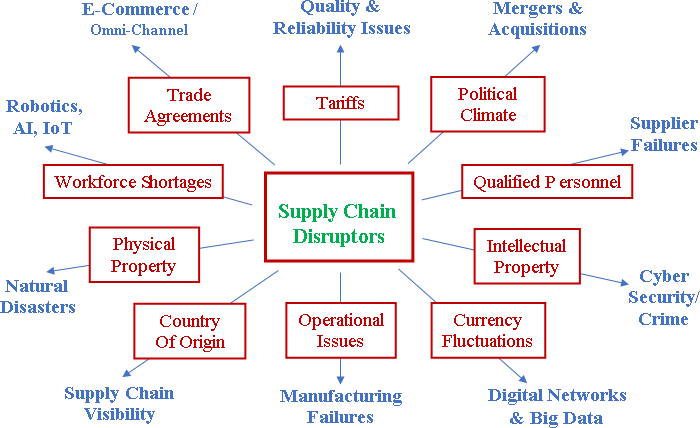

Common disruptors include supplier issues, technology-related (including information technology, data and cybersecurity) issues, environmental/climate change, new regulations and brand issues. The graphic below highlights industry-specific disruptors that were identified during the CPO interviews, shown in red. Other common disruptors — identified in industry research articles, studies, blogs and other media sources — are in blue.

Industry Disruptors

Most modern-day disruptors’ impact has been detrimental to numerous global supply chains from the perspectives of finance, operations, sustainability, assurance of supply, and other functions. Moreover, several recent studies have reported that supply chain disruptions are growing at an alarming rate. A closer look at major disruptors and impacts:

Brand and reputation. Brand and, more importantly, reputation are important to global corporations. A prolonged supply chain disruption can materially impact a company’s financial performance, resulting in temporary worker layoffs and wavering customer loyalty. In recent years, for example, companies like Ford Motor Company, KFC and The Boeing Company have had corporate reputation-tarnishing supply chain disruptions. A fire at a Ford supplier factory, for example, disrupted production of the F-150 pickup truck. An operational disruption by a new third-party logistics partner for KFC closed half its stores in the United Kingdom.

Big data and new regulations. Data security and privacy — especially customer-data security — are constant and growing concerns for global corporations. Compounding these concerns are ever-changing regulations and requirements that differ by geographic locale, thus increasing business risk and creating barriers for supply chain professionals. One such regulation, the European Union (EU) General Data Protection Regulation (GDPR) in 2018, forced global corporations to reassess and think smarter about data protection. Failure to comply with the GDPR will have consequences to a corporation’s bottom line, customer relationships and brand image.

Governments recently began to raise data privacy and protection concerns regarding technology platforms operated by Apple, Google, Facebook, Twitter and other corporations. Ramifications of data breaches will be costly to global corporations.

Supply chain visibility. For most companies, monitoring and tracking the flow of materials and goods is challenging. Unfortunately, the necessary technology that must be in place to support supply chain visibility is not always adequate. Cybersecurity attacks are also increasing daily, with major repercussions for corporations.

Additionally, governments are increasingly requiring companies to identify country of origin, chain of custody and traceability of materials and goods in their supply chains. A failure to comply risks significant fines and/or other restrictions.

Supplier failures. These result in operational, financial, IT and qualification risks.

Supplier risk management is increasingly important to corporations as they fine-tune lean supply chains and shorten last-mile delivery times. A tight supply chain can be disrupted by such events as factory fires, shortages of drivers and distribution-center workers, bankruptcies, electronic logging device glitches and other operational problems. These problems have heightened the impacts of supplier risks on global corporations both financially and operationally.

Natural resource shortages. There is a growing demand for limited resources. Published articles, studies, blogs and other media have reported the threat of potential future shortages of natural resources like water, oil, natural gas, phosphorus and rare earth minerals like scandium and terbium.

The critical challenge for many corporations is mitigating the risk caused by scarcity of natural resources. Corporations are currently focusing on experimenting and testing environmentally friendly and renewable-resource solutions. However, they are not routinely implementing these innovations into their supply chain procedures.

Climate change and natural disasters, like catastrophic weather events. Climate change impacts infrastructure and disrupts logistics, suppliers and customers. These negative impacts significantly affect entire supply chains. In 2018, the U.S. recorded its 14th-warmest year on record, and all-time temperature highs occurred throughout Europe and the Arctic. In recent years, hurricanes hitting the U.S. have resulted in billions of dollars in damages. In 2018, Hurricanes Michael and Florence totaled more US$49 billion in damages. Also that year, wildfires in the Western U.S. totaled $24 billion in damages, a record for a single year.

Natural disasters impact global supply chains and reshape industry precautions. Of the numerous threats to global commerce, natural disasters are unpredictable and nearly impossible to prepare for in advance. In 2018, extreme weather led to serious disruptions of global supply chains, with operational, financial and strategic impacts on businesses.

Catastrophic weather can make necessary resources and materials a challenge — if not impossible — to source in many situations. Droughts have caused an corporations to be increasingly concerned about water shortages.

Shift in critical skills. A skilled talent shortage is one of the top external forces impacting supply management, as qualified professional skills fail to keep up with evolving technologies and capabilities necessary to manage supply chains. A 2018 Deloitte study indicated that over the next decade, as many as 2.4 million manufacturing jobs will go unfilled, which will jeopardize more than $2.5 trillion in economic output.

Digital trends, cloud technology and other innovations are impacting global supply chains, and as a result, leaders must build organizations that can withstand these significant and fast changes or disruptors. DHL, a global leader in the logistics industry, warned that the impact of digitalization alone will exacerbate the talent-shortage crisis.

Global Industry Boardroom Insights

Additional industry disruptor research uncovered insights on challenges and opportunities for global supply chains. Key highlights include:

•Supply chain disruptors play a prominent role in boardroom discussions since they directly impact components that drive corporate profitability and results. Specifically, many boards are focusing on solutions regarding downstream (Tier-2 and Tier-3) suppliers, while others concentrate on building supply chain visibility.

•Some corporations already recognize the future impacts of disruptors and are starting to implement mitigation programs. For example, financial companies are working with major supplier groups to respond to disruptions.

•Many corporations have identified a need for improved collaboration and operational planning with business entities and governments, across entire supply chains. For example, banking-industry corporations are collaborating to mitigate cybersecurity risks.

•Solutions to mitigate or eliminate disruptors require a multifaceted approach that integrates important internal corporate functions, systems, customers, suppliers, government regulators and/or third parties. For example, tariffs on glass and steel not only impact the costs of the materials, but other ancillary costs like insurance and taxes.