Enhancing Logistics, Warehousing and Transportation with AR and VR

Editor’s note: This is the sixth in a series of 10 articles about advanced technologies and what they mean to procurement. Articles run on the second and fourth Tuesdays of the month in Inside Supply Management® Weekly, Institute for Supply Management®’s (ISM®) e-newsletter.

***

The logistics industry is undergoing a significant transformation with the integration of such technologies as augmented reality (AR) and virtual reality (VR). They provide immersive experiences that can enhance warehouse operations, order picking and transportation management, while also improving efficiency and accuracy.

In warehouses, for example, AR enables workers to overlay digital information onto their real-world view, providing them with real-time guidance and information. By using AR headsets or smart glasses, workers can visualize item locations within the warehouse, receive step-by-step instructions for picking and packing, and access real-time inventory data. This reduces errors, minimizes training time for new employees, and optimizes warehouse layout and organization.

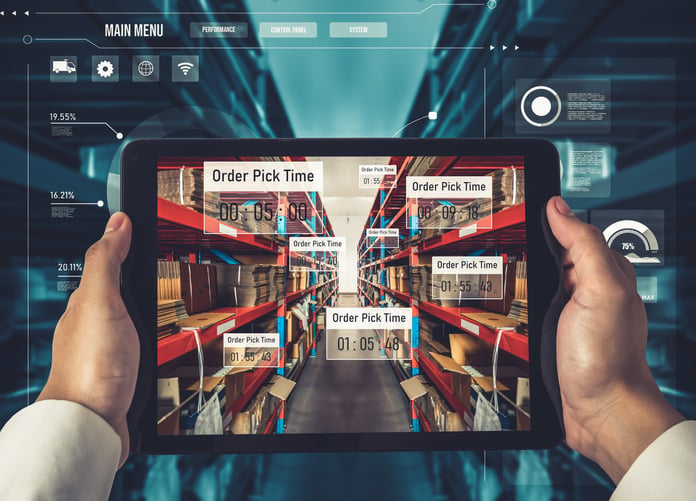

AR and VR can also significantly improve the efficiency and accuracy of order picking, a labor-intensive and time-consuming process. Warehouse workers can use AR to view digital overlays that guide them through the most efficient routes for picking items from shelves. They can also see real-time information about the quantity, location and specific details of the items to be picked. This technology reduces errors, shortens order fulfillment time, and improves overall customer satisfaction. VR can also be used to simulate order picking scenarios, allowing employees to train and familiarize themselves with warehouse layouts and procedures in a virtual environment.

A variety of factors, from weather to traffic, can disrupt deliveries and transportation management. But with AR, drivers can receive real-time navigation instructions overlaid onto their field of vision, reducing distractions and improving safety.

AR can also provide drivers with valuable information about traffic conditions, road hazards and alternative routes. Additionally, VR can be used for driver training, enabling drivers to practice various scenarios, such as loading and unloading procedures, vehicle inspections and emergency situations. This enhances driver skills and prepares them for real-world challenges.

Remote collaboration and maintenance also can be accomplished with AR and VR. Using AR, experts can remotely guide on-site technicians through complex maintenance or repair tasks by overlaying digital instructions onto their view. This reduces the need for travel and expedites problem-solving, leading to faster resolution times and reduced downtime. VR can also facilitate virtual meetings and training sessions, enabling geographically dispersed teams to collaborate, learn, and share knowledge without physical presence.

The cost of acquiring and maintaining the necessary hardware and software can be significant. Integration with existing systems and processes may require careful planning and customization. Training employees to use AR and VR technologies is crucial to ensure successful adoption. Data security, privacy and connectivity issues should also be addressed to safeguard sensitive information.

By leveraging AR and VR, logistics companies can streamline operations, optimize resource utilization, and provide better customer experiences. As technology continues to advance, the adoption of AR and VR in logistics will become increasingly prevalent, driving the industry towards greater efficiency and innovation.