Protecting Human Rights Through Supply Chain Visibility and Data

When it comes to modern slavery, forced labor and child labor, supply chains can be the solution, not just the problem, says Justin Dillon, CEO and founder of San Francisco-based FRDM, a software-as-a-service provider. “End-to-end visibility into the supply chain along with better data management is the way we improve business and the issue,” he says.

Most companies barely have visibility into their supply chains, says Dillon, whose company name is pronounced “freedom.” While the advent of ERPs and supply chain management software in some ways has allowed us to buy and sell much more quickly, the complexity and disjointed data in these systems hides a lot of forced labor risk, he says.

As third-party vendors and providers handling the procure-to-pay process, sourcing and procurement for many organizations, “companies don’t really know what they’re buying and who they’re buying it from,” he says. “Less than 5 percent of companies have real visibility into their supply chains. That means 95 percent of companies don't know where things are coming from.”

New laws and regulations around the world are designed to restrict organizations for sourcing from suppliers that utilize modern slavery tactics. The U.S. Uyghur Forced Labor Prevention Act (UFLPA), which took effect in June 2022, prohibits the import into the U.S. of goods manufactured wholly or in part with forced labor in China, particularly from the Xinjiang Uyghur Autonomous Region.

“A supplier that you think is great could be doing business with a sub-supplier that is deemed dangerous, and therefore the U.S. Customs & Border Patrol can seize anything you buy from the direct supplier,” Dillon says. “A lot of shipments are being seized at the border due to potential forced labor infractions.”

Germany has a similar law, the Act on Corporate Due Diligence in Supply Chains (Supply Chain Due Diligence Act), that went into effect January 1. It applies to companies with their headquarters, branch office or principal place of business in Germany that have 3,000 or more employees (1,000 employees as of 2024). It requires companies to have conduct a risk analysis and due diligence pertaining to human rights and imposes penalties if risks aren’t dealt with.

“So, the burden on companies to start to map their supply chains is very high,” Dillon says. “The problem is that a lot of companies still use questionnaires and audits with their suppliers to achieve this. Those are now insufficient tools. They were great in the first part of this century for helping companies gear up for globalization, but now look like a cold war playbook for a 21st century problem. Now, having auditors visit factories and ask questions is not sufficient to map your supply chain. And quite frankly, there are places in the world now where auditors are not allowed to go, which is a huge risk. Relying on supplier questionnaires alone is risky because on average less than 30 percent of suppliers even respond.”

Plus, questionnaires and audits are an “analog” way of dealing with supply chain visualization, looking backward, not forward, Dillon says. Having the right data can make the difference, he says.

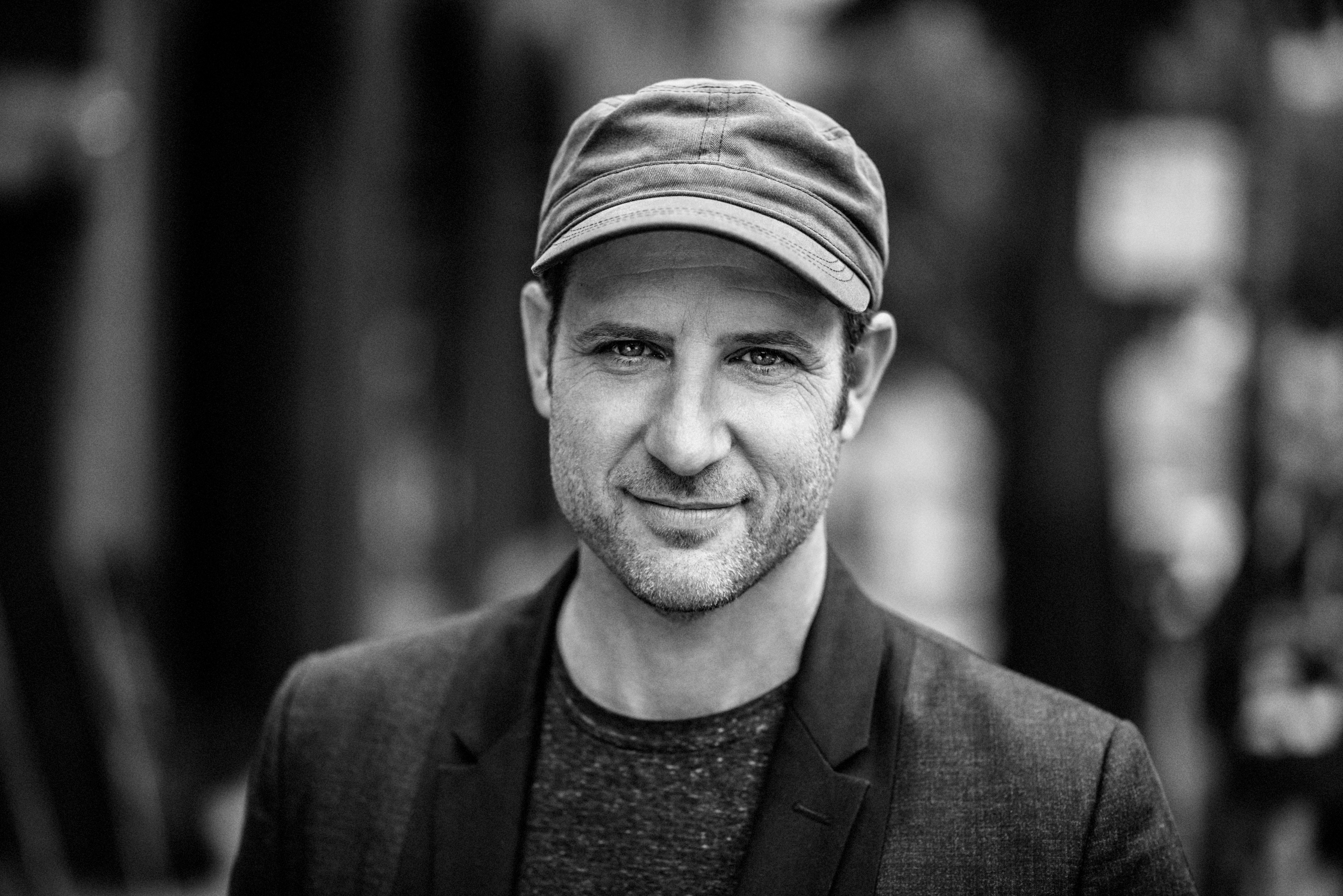

Justin Dillon, CEO and founder of FRDM, believes supply chain transparency will be the norm soon because businesses, people and the planet will “require it.”

Author of A Selfish Plan to Change the World: Finding Big Purpose in Big Problems and a former professional musician, Dillon has sought to create greater awareness about modern slavery and how supply chains can help solve the problems for more than 10 years. He and his team developed slaveryfootprint.org with the Obama Administration and Google; the site enables consumers to understand their own human rights-related footprint — “how many slaves it takes to run your life,” he says.

The website doesn’t contain brands — “we intentionally made it brand-agnostic because I don’t believe in pointing fingers,” Dillon says. “We hoped when we launched it 10 years ago that we’d get 150,000 people to know their slavery footprint. But today, there’s about 33 million people who know their footprint today. That’s a lot of consumer awareness.”

For companies, gaining greater supply chain visibility requires investment in new technologies and new innovation, Dillon says. While supply management hasn’t traditionally been the function where such investment in technology occurs — sales is one area where it often does — he says the last two years have seen major investment in supply chain tech.

“Supply chain is having a reinvention and a digitization, and we’re moving away from analog approaches,” he says. Regulations and trade enforcement are increasing pressure on businesses to invest in appropriate technologies. “Laws are requiring procurement professionals to take a more proactive stance on these issues and instead of just reacting when something comes up,” he says.

Dillon calls it a “very different exercise for organizations to be more proactive and intentional.” For example, FRDM uses simple invoice level spend data to map its customers’ supply chains — “the data will tell you where to look for risk and how to fix it,” he says.

“I believe that in five years, most supply chains will be transparent because our businesses, our planet and the people who live on it require it,” he adds.